VDG-Nachrichten 02/2021

Japan - Tokyo: Hideaki Hashimoto's

glassblowing workshop

Japan - Tokyo

How do you write “glassblowing” in Japanese? Very simple: 吹 き ガ ラ ス Just writing it shows how diverse working life on our planet is. We invite you to Tokyo to visit a specialist who is by no means unknown to the VDG. Hashimoto Hideaki is self-employed and runs a glassblowing workshop in the Japanese capital. In the following pages, he describes his career, his company and how he came to all of the specialist knowledge that he has implemented so successfully.

Academic and professional education

After graduating from high school, I joined a company run by my father. I learned the first steps of glassblowing from one of my employees. It was a simple task, so I got tired of it easily. I learned about the existence of the Science Glassblowing Association in Tokyo and immediately joined.

The organization has many excellent professionals, some with very good advanced processing techniques. As you know, glass processing has a long and secret tradition. I don't really show my workshop to anyone. Also, I don't go to other people's workshops. There is an implicit agreement between experts on this.

Even so, I got acquainted with a young person from the organization who taught me the processing technology there. He taught me many basics about using lathes and other tools and aids.

This scientific glassblowing association has 6 sections in Japan, and 82 companies participate in it. The Japanese association is not for individuals as much as it is for corporate companies. I improved my skills, aiming for the scientific glassblowing level 2 skill test of this organization. The requirements for the qualification are 5 years or more of work experience, production of a "condenser / arin / 500mm" and passing a written examination.

To complete this exam, I learned techniques in various fields. After passing the exam, I aimed for the Level 1 exam. I learned the required skills in parallel with working as an independent glassblower. The examination consisted of manufacturing a Soxhlet extractor and passing a theoretical test. I passed this exam. I also attended events around the world, such as VDG meetings, to meet colleagues, build relationships and gain experience. Thirty years after I started, I also became the chairman of the Tokyo organization and the chairman of the national organization, but now I have retired from those positions.

Unfortunately, the number of test subjects has dropped significantly and we had to discontinue examinations. However, the organization continues to offer training courses with technical and scientific presentations to teach young people the art of glassblowing.

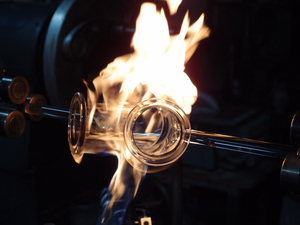

Meeting colleagues, establishing relationships and gaining experience. Hideaki Hashimoto at a screening at an ASGS symposium in the United States of America. Here he is making a double-walled vessel with a volume of 500 ml.セパラブルフラスコ 500mlにジャケットを付けて、水冷が出来る構造です。 内部のフラスコとフランジ部分を製作後に外側を溶着し、水冷ノズルを付けます。

In 2010 I received the -Heisei 22- Tokyo Master Award. The award was given to engineers of the Tokyo Metropolitan Government

Buy - sell, change or leave it as it is.

Customer requirements have changed over time. They want cheap products, but of absolutely high quality. This is difficult to achieve with the resources currently available. Since our premises are very narrow, we cannot buy larger and more modern machines. That is why we increase the efficiency of our machines in-house and invest in good tools. Japanese glass tube manufacturers are relocating their factories to Southeast Asia because domestic production is expensive. Nonetheless we continue to buy glass tubes, piston blanks, connections, etc. in Japan. However, we source our glass processing tools such as graphite or diamond tools, heat-resistant tapes, etc. from overseas. In addition, there are increasing environmental regulations that require investment. It's expensive to expand by moving because Tokyo is expensive. The only reason why I hesitate to move our workshop to the country is the good location of our workshop with easy transport routes and the proximity to my place of residence. Our company is just a few minutes' walk from the train station and very close to a wide street

Insights into the production

Product range

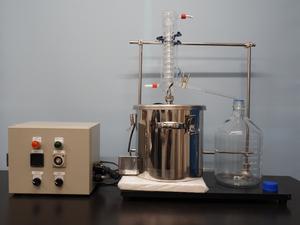

Our glass products are supplied to corporate and university laboratories. Of course, dealing with repairs is also part of the service. Our equipment that extracts essential oils from plants is also sold to professionals.

More about this at:

https://tokyoss.co.jp/

We also develop, produce and sell glass tube cutters. I use this glass cutter every day and am happy to have the opportunity to present it here. Video about Hideaki Hashimoto's glass cutter at:

https://www.youtube.com/watch?v=EM3EOGHfro8&t=7s

Working hours, vacations, vacations and health in Japan

We usually work 8 hours a day, and Japan has national holidays + summer holidays + year-end and new year holidays. These add up to around 40 days a year. As a self-employed person, of course, I can't really enjoy these times. I also have to work during vacations and public holidays if the order situation requires it. Health must also be taken care of. My father and I work together in our company. Once a year there is a health check for each of us. By the way, my father is 94 years old and still comes to work every day.

Challenges and goals

Unfortunately there is no successor for me. I am 61 years old and will be working for another 10 years. Now I think it is very important to impart my knowledge and manual skills to young people. That's why I made a video about processing glass and put it on the server of our glass association.

Thank you for the cooperation from Thomas Niess to Hideaki Hashimoto

橋本秀秋 トーマス・ニース

Kontakt, Anfragen und Anzeigenschaltung:

Redaktion des VDG e.V.

c/o Eberhard Karls Universität Tübungen

CZI Glasbläserei

Karin Rein und Thomas Nieß

Auf der Morgenstelle 6

72076 Tübingen