Glass apparatus Scientific Glassblowers in the Kingdom of the Netherlands

Not for the first time are we visiting one of our neighboring countries in the north with our journal. You may remember how we reported about Jens Christian Kondrup in our 02/2020 issue, who we all know as an excellent colleague and who works at Denmark's second largest university, Aarhus University. Now we travel to the Netherlands, to Adriaan Hendrik van der Weel. He is a scientific glassblower through and through. What does training for this profession look like in the Netherlands, how in demand are you as a specialist there and how can you continue your education in our neighboring country if you want to achieve more, much more than many others?

VDGN 4/2022

I am pleased to introduce myself. My name is Adriaan Hendrik van der Weel (Aad), born in Amsterdam in 1991, grew up in Leiden and later in Zeist. Glass has been my passion and my life for years, but I actually came across it by accident. After graduating from high school, I had little idea about what exactly I wanted to be. The only thing that mattered to me was that it had to do with a craft. The only thing that mattered to me was that it was professional training. Metalworking was my main interest and after looking into some professional training courses (MBO-opleidingen) in industrial design and mechanical engineering, I finally and luckily ended up at LiS, the Leiden Instrumentmakers School, thus returning to the city of my early childhood.

Lis, the instrumentmakers school in Leiden/Netherlands since 1901

The LiS has been training scientific glassblowers for 120 years. This is due to Nobel Prize winner Prof. Dr. Heike Kamerlingh-Onnes (1853-1926). He commissioned foreign craftsmen to train talented young people to make glass apparatus

What do I learn during the training at LiS?

First year

In the first year, the focus is on the basic manufacturing processes. You will learn turning, milling and glass blowing, both computer-controlled and manual. You will learn how to operate the machines for the production of apparatus independently and safely and assemble these parts into a precision instrument.

Second and third year

You enter into the manufacture of more complex instruments. You will delve deeper into the use of materials, construction and the manufacturing process. You will also learn about the electronics required to operate an instrument and the sensors required for measurements. During your internship you will apply what you have learned.

fourth year

During the final year, you will practice translating customer queries into a solution - the precision instrument - that the customer can use to conduct their research. There is also a final internship.

What can I work as afterwards?

You are a trained scientific glassblower and can work in:

Research & Development

High tech industry

Medical technology

Aerospace

After graduation, further training in the area of mechanical engineering, for example mechatronics, is possible!

LiS staff

The employees are characterized by great enthusiasm and commitment to the LiS and its students. Around 40 employees work there, 80% of them in education and 20% in support.

I was immediately hooked

and started my apprenticeship in 2008.

Originally, of course, I came there because of my interest in metalworking. It was only at this school that I got to know scientific glassblowing.

The first school year is usually an orientation year, in which you also have to complete basic exercises in the glassblowing workshop and in the optics workshop, even as an apprentice in metal work.

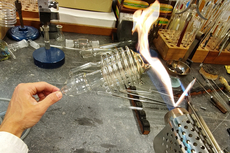

So I first learned to draw tips from AR glass, make T-pieces and transition pieces, blow balls and form arches, etc.

At the end of the first school year, students are selected based on their talent. This means that the school only selects those who have demonstrated aptitude for the subject to make glass instruments. Only they can specialize in scientific glassblowing for the rest of the training and also take their final exams in this area. (They start working with borosilicate glass in the 2nd year.) I was one of the lucky ones who had the choice to go into glass, and I left metal behind in 2009.

I didn't know what was to come, but it seemed like a very nice job and I saw a nice future in it. But I already noticed when I was allowed to learn the basics that it is a difficult craft and that the beautiful work is unfortunately not suitable for everyone. However, my enthusiasm was such that from the moment I was accepted into glassblowing, I decided to do my best to practice the craft.

Moments of Motivation

The school had showcases full of beautiful equipment and there was a small attic above the glass workshop which also held cupboards full of old work, including many masters’ final projects.

I often looked at them, sometimes I just went there to study them a little and let the impressions work on me.

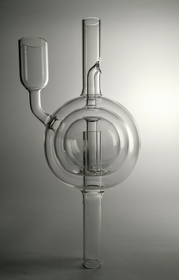

There was also a copy of the famous liquid nitrogen sphere cooler that really impressed me. This piece seemed so utterly impossible, it was complete madness, and yet it was apparently doable. I wanted to be able to make this piece one day! At the time, I wasn't even aware of how intensively I would have to practice until I succeeded.

But that goes for most pieces. Glass just fascinated me! I studied the shapes, imagined the creation processes, and then tried out what I had come up with in the workshop.

We were shown some basic techniques, but we also had to teach ourselves a lot and I was fine with that. I could be found in the workshop every available moment, sometimes even during the holidays when the teachers were also working.

The basic tasks that I had to do for the apprenticeship were done quickly and I used the time to playfully explore the development of more complicated challenges.

It often took me a lot of time and fumbling to put together a piece of work like this, but it worked out in the end and that was a great joy.

I think, looking back, I can say that I progressed quickly, but it still took me a long time just to learn how to work not only accurately, but also quickly and effectively.

The fun alongside the training

My school days were very pleasant. I lived in a student apartment in Leiden and was active in the school's student council. We organized parties, outings and dinners, and every year we hosted an introductory week for the new first years, which I also joined as a leader in my later school years. It was a very nice time and I made a lot of good friends. The classmates in the glass workshop were like one big, loving family. All this has certainly contributed to a great sense of well-being.

However, this was partly at the expense of studying the theory subjects, which ultimately delayed my training somewhat. I didn't find it that problematic myself because life was fun and I was able to put the extra time in the glass workshop to good use.

In 2010 I was allowed to do an internship at Eindhoven University of Tech (Tu/E) where I learned a lot from my assigned teacher Ad Waterschoot. An internship lasts about 5 months. During this time you will attend theoretical subjects at school two days a week and you will spend 3 days in the internship company. Later I was able to do an additional internship at the Shell Technology Centre in Amsterdam, which was a prestigious place for a student. There, too, I was able to learn beautiful techniques and see how large glass reactors are made.

The successful diploma, with distinction

When I finally successfully completed all theoretical subjects in 2013, I was allowed to take my scientific glassblowing diploma, which I passed cum laude (with the highest praise).

After that my first job was in the Tu/E glassblowing workshop, but now as a skilled worker and colleague, where I learned a lot from Ad in hot glass processing. We worked there mainly for the faculty of chemistry, but also for technical physics. I also learned how to work with quartz glass, which is often used in physics laboratories.

The processing ranged from table work to small and large turning work. But maybe the best thing I learned back then was how to melt Borofloat, I was able to make some glasswork out of it and that was an experience I benefited from later on.

During the first six months I worked there, I also made the liquid nitrogen sphere cooler that I always admired in the school's glass case.

But I also spent countless evening hours making many creative pieces for myself or colleagues and sometimes for students of the Design Academy.

I worked there for three years, then I was offered a job in the north of the country at Lgs ( Laboratory Glass Specialist BV ) in Ubbena. Later Lgs moved to Assen.

I only worked there for a year until I got a job in the glass workshop at the University of Groningen that interested me, so I switched again and worked there from 2017 to 2022.

A job at the university is not for everyone

For a long time I felt very comfortable in the university workshops. The work that was offered there was quite diverse and there were interesting tasks from time to time. I had good colleagues and the direct contact with the customers was often very nice. But it was also often quiet and the more I practiced and gained experience, the faster I got the job done, which sometimes gave me even more free time! Luckily, I had my boss's permission and support to practice when the workshop was slow. I really enjoyed it for a few years. I liked the freedom, and practiced and experimented a lot with glass. But I missed the challenges more and more.

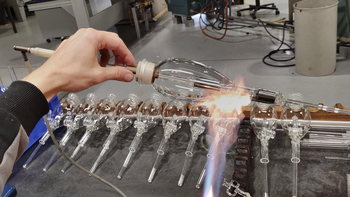

I've been back at Lgs since August this summer, now in the beautiful new workshop in Assen. The work there is much more demanding than at the university and I was really looking forward to that, including working with my best friend Wouter. I really enjoy producing again. We make beautiful glass work there.

I have kept in touch with this company frequently over the past five years, partly because Lgs has a partnership with the University of Groningen and is a supplier of glass tubing and semi-finished products for further processing. I also worked together with my colleague and friend Wouter for about 10 months in the Lgs workshop almost every Saturday to make masterpieces in preparation for the Leiden fellow’s examination, which we took and passed together in 2019.

Training in the Netherlands

The Leiden training system has three levels: Apprentice, Fellow and Master, or glass A, B and C. If you have successfully completed the training, you can work as a scientific glassblower, as in Germany. Similar to the German system, but fellow and master titles are used a little differently here.

After you have gained a few years of professional experience, you can register for the fellow and master craftsman's examination, which is held in the glassblowing workshop at Lis. For this you have to come to Leiden for a week. However, that doesn't happen very often anymore. The last time was with us in 2003 and since then there have been hardly any other candidates. For the C-level it has been even longer, more than 30 years.

This is not really surprising as it is quite a hard exam in terms of difficulty and time pressure, and it also contains old-fashioned exam items, such as a ground valve, which are technically challenging but no longer encountered in everyday working life.

But that shouldn't be a problem for us, because it's our dream to one day also take the C-examination, especially since we've already been given many such tasks. The biggest challenge is the working speed. The time available is really minimal and in the past, few have managed to pass the C exam. But it's just a great joy to keep this craft alive and it was nice to see how our B exam inspired the young glass students.

Two friends who support and advance each other

Wouter and I are good friends and our level of craftsmanship is quite similar. He's more skilled at big machine jobs and I at the small table jobs, but we both do pretty much everything, both live in the city of Groningen and are often together outside of work. We share a broad interest in craftsmanship and, in addition to our everyday work, we like to study traditional working techniques. I was once allowed to copy a thick stack of technical drawings from old fellow and master craftsman exams from the archives of the Leiden instrument making school. Reproducing these drawings has been an important means of expanding our practice.

Apart from the basics and a few unusual tricks that we learned in school, as already mentioned, we also had to work out a lot of processing techniques ourselves. It often happens that we approach workpieces in different ways, only to find that each method has its own advantages. So we could and can learn a lot from each other. In addition, it is valuable and interesting to link old knowledge with the knowledge of today.

Workplace options as an employee

There are interesting jobs for specialized scientific glassblowers in the Netherlands, but unfortunately they are not very plentiful. One of them is certainly at Lgs. The Lgs and I have long been interested in a new era of collaboration. The company has become more modern. Wouter and I now have flexible working hours. We can also make something for ourselves or practice in the evenings or at the weekend.

Besides working as a scientific glassblower, I work with coloured glass one day a week, in a an art workshop in the city where I am good friends with the owner. I have a burner there that I can use to create small items. I also do a bit of Tiffany work and of course I give Christmas bauble workshops during the winter months. But my capacity for larger dimensions has always been a bit limited there and that's why I'm happy to be able to play with big fires again, which I can now do outside of working hours in the Lgs workshop.

The combination of technical forms and free, artistic design is something I would like to explore further. So far I have only been able to produce a few pieces born from this idea. But many designs are still waiting and I can't wait to make them!