VDG-Nachrichten 03/2020

Stainless steel mesh - a real substitute for asbestos

My favourite part of the VDG-News is the section presenting tools or materials which every good glassblowing workshop should not be without. So I would also like to present a material that I use every day for a wide variety of work processes and for which, for me, there is absolutely no alternative – interwoven stainless steel.

For a layman it is hard to imagine how stainless steel can be processed into different designs. About 15 years ago, when Mr. Raf Claes from the Belgian company Bekintex presented me with samples of stainless steel mesh mats at Munich Airport, I had no idea how much easier this material would make my daily work. Finely spun and woven stainless steel is as soft to the touch as the ordinary cloth fabrics that we wear every day. The woven material is available in countless designs, from tubular stocking shapes to matted material several millimetres thick, all with the wonderful properties of stainless steel.

heat-resistant up to 750°C

100% high-purity stainless steel

soft, but still easily compressib

easy to cut with scissors or knife, but still completely tearproof

table in its form over decades

when dirty, easy to burn off in a kiln - afterwards like new

the fabric does not fray through the years - on the contrary, the edge of the mat is sealed by flame contact and still remains soft

This material is used in the glass casting industry wherever the hot glass, still glowing but already stable in form, comes into contact with foreign material for the first time. For example, the conveyor belts in the kiln or the surfaces of clamps and underparts are covered with these stainless steel mesh mats so that the red-hot glass bottles don’t bang into each otheregt.

Videolink: https://www.youtube.com/watch?v=Khde8qjHzNs

Where this stainless steel material is used in my glassblowing workshop:

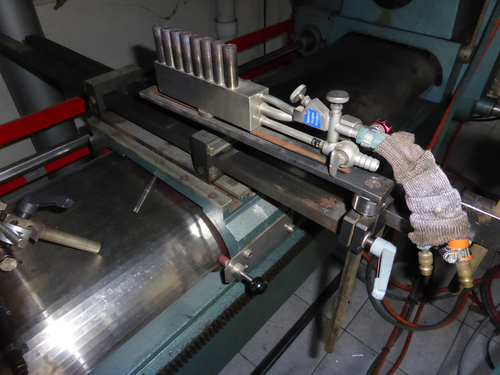

1. At the glass lathe on the chuck jaws.

Here I use approx.10cm long, 2cm wide and 3mm thick Bekintex mats with the product number NP 250. I simply place the mats loosely between the glass body and the three-jaw chuck, so the chuck can be fully tightened. The mats are elastic enough that the glass is not crushed and the glass object can easily be knocked into place with the back of the hand.

2. Spacer strips for double-walled melts.

To obtain the desired thickness, several strips can be placed on top of each other. In this way, distances that are sometimes centimetres thick can be bridged and fixed. When cold, the mats can be inserted easily and without scratching. When heated, the material expands and so firmly holds the part to be melted. The stainless steel strips can also remain in the glass piece during the relaxation process. After cooling, they can be easily removed without leaving any residue.

For high-filigree melting, as here in the production of the Covidvirus, please see VDG edition 02/2020.

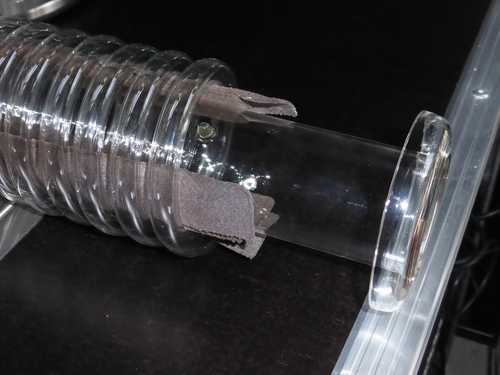

3. The hose stocking form is used to insulate my gas-oxygen supply line to the burner.

Stainless steel mat in the form of tubular stockings, to insulate the gas and oxygen pipes.

4. With highly filigree melts, adjacent cold glass pieces can be shielded.

For this purpose I use a thin stainless steel fabric which covers the glass object. Exactly at the point where a melt is to be performed, I cut a hole in the fabric with scissors, which is comparable to a surgical drape. Inside the hole it is possible to work without getting adjacent areas dirty or, in the case of hot glass, without tension due to flame flashback.

Stainless steel mat as spacer strips for double-walled melts.

5. As stainless steel curtain material

Sometimes during the relaxation process I have to work on the glass with a hand torch at 550°C. A stainless steel curtain fabric allows me to open the large annealing kiln at 550° and to pull out the sliding plate on which the glass is placed, so that only the part that really needs to be worked on is out of the furnace. Instead of the oven door, the stainless steel curtain now shields the heat so that the full heat remains in the oven.

As a stainless steel curtain for screening, here during the production of an armadillo skeleton.

The fabric fits snugly around the shape of the glass so no kiln holes appear. The thin, not even 1mm thick fabric is thick enough to perfectly shield the 550°C temperatures. Approx. 20 cm behind the stainless steel fabric you can work with the hand torches without gloves or protective clothing. During the work, the curtain can be lifted slightly and the piece of glass can be pushed back into the oven to relax. This procedure can be repeated several times and would not be possible without this ingenious material.

6. As a door curtain for medium sized workplace furnaces (e.g. Paragon, Skutt).

In such table-top annealing kiln, the door opens upwards in a plane-parallel manner. This means that the moment a work piece is pushed into the furnace, the furnace temperature can drop by 100°C in this one second and needs several minutes to get back up to 550°C. A stainless steel curtain with a central, vertical slot ensures continual effective working, while preventing most of the furnace’s heat from escaping upwards through the door gap when the door is opened.

Numerous other applications in my workshop have done away with asbestos, ceramic fibre materials, refractory papers and even graphite fabrics.

Visits to my workshop in recent years have shown me that this material is not at all common among lamp glassblowers.

Important!! Before using these materials, it is essential to let them anneal in an oven at 550°C. Afterwards you have a stainless steel product in its purest form.

If you are interested, more information is available at:

https://www.bekaert.com/en/products-and-applications/

Direct contact Raf Claes:

Ian Barnes is the owner of the Englisch Institut in the Tyrol, Austria.

This article was translated into English by him, allowing it to be read in German and English on the website. We are grateful to Ian Barnes and Bernd Weinmayer for their contributions.

Read the article in german.

VDG-Nachrichten

Herausgeber

Verband Deutscher Glasbläser e.V., Karlstr. 7, D-48268 Greven

Erscheinungsweise

vierteljährlich im März, Juni, September und Dezember (Sonderausgabe nach Bedarf)

Format

210 x 297 mm (DIN A 4)

Bezugspreis

Der Mitgliedsbeitrag beinhaltet den Bezug der VDG-Nachrichten; Bezugspreis für Nichtmitglieder: 13,50 €.

Druck

Karl Elser Druck GmbH, Mühlhacker / E-Mail: info@elserdruck.de

Kontakt, Anfragen und Anzeigenschaltung:

Redaktion des VDG e.V.

c/o Eberhard Karls Universität Tübungen

CZI Glasbläserei

Karin Rein und Thomas Nieß

Auf der Morgenstelle 6

72076 Tübingen